Is your fleet running at peak performance, or is it idling in the slow lane?

Whether you’re commanding a squadron of semi-trucks or an armada of ambulances, the secret to steering a successful fleet lies in the numbers.

But not just any numbers – fleet management KPIs, the critical fleet metrics that drive performance and efficiency.

In the world of fleet management, what gets measured gets improved.

And we’re here to put you in the driver’s seat with our comprehensive guide. So, strap in and keep your eyes on the road as we navigate through the 12 fleet management KPIs every fleet manager should track.

What Are Fleet Management KPIs?

Fleet maintenance Key Performance Indicators (KPIs) are critical for any fleet business to maintain operational activity and achieve growth and objectives.

Fleet KPIs serve as objective metrics to assess your fleet operations’ efficiency, effectiveness, and overall performance. In the context of fleet management, they measure various aspects such as cost management, vehicle maintenance, driver performance, safety and others.

Here are some examples of Fleet Management KPIs that we’ll look into in the following sections:

- Fleet Utilization

- Cost Per Mile

- Fuel Efficiency

- Total Cost of Ownership (TCO)

- Preventive Maintenance Compliance

- Average Vehicle Downtime

- Repair Costs

- Vehicle Part Inventories

- Safety Incidents Rate

- Driver Productivity

- Speeding, Acceleration and Harsh Braking

- Road Safety Compliance

The Difference Between Fleet Management KPIs and Metrics

From a bird’s eye view, both Key Performance Indicators (KPIs) and metrics are used to measure performance, efficiency, and success. At the same time, they serve different purposes and have different implications.

Fleet management metrics are quantifiable measures used to track and assess the status of a specific business process. They are basically raw data that provide insights into various aspects of your fleet operation.

On the other hand, Key Performance Indicators are a subset of metrics that are aligned with strategic objectives or goals. They are carefully defined and measured to gauge the performance of the business.

In a way, fleet management KPIs are the metrics that matter most to achieving success. They are often time-bound and are used to evaluate the success of a particular activity.

Why Do Fleet Management KPIs Matter?

Now that we’ve laid the foundations, it’s important to answer a common question – why do fleet management KPIs matter?

As a business, your fleet KPI system is crucial for several reasons:

- Data-driven decision making

- Performance monitoring & improvement

- Cost management

- Risk mitigation

- Benchmarking & goals setting

- Operational efficiency

Put simply, fleet management KPIs empower fleet managers and owners to make data-driven decisions, and act in the best interest of the business at all times.

Naturally, every fleet management KPI serves its unique purpose. In this article, we’ve split fleet KPIs into three core categories:

- Efficiency KPIs For Fleet Operations

- Fleet Maintenance KPIs

- Driver Behavior and Activity KPIs

Efficiency KPIs For Fleet Operations

The first fleet management KPI category we explore is efficiency KPIS for fleet operations.

As the name suggests, these KPIs are used to measure how effectively and efficiently your fleet is operating. They include the following:

Fleet Utilization

Fleet utilization is a fleet KPI used in fleet management to assess the efficiency and effectiveness of a fleet’s usage. It clearly shows how much your fleet’s assets are being used and how much they sit idle.

A high fleet utilization rate suggests that your fleet is utilized effectively, whereas a low rate signals that there may be opportunities to boost efficiency or perhaps reduce the fleet size.

There are plenty of ways to measure fleet utilization:

- Time-based utilization – measures the percentage of time a vehicle is being exploited versus the time it is idle. For instance, if a vehicle is in use for 6 hours a day (where a full day is considered to be 24 hours), its utilization rate would be 25% for that day.

- Distance-based utilization – looks at the total miles a vehicle covers over a certain period. If a vehicle is driving fewer miles than expected based on company standards, it may be underutilized.

- Load-based utilization – for freight and logistics fleets, utilization could be based on the vehicle’s capacity. For example, If a truck is designed to carry 20 tons but regularly carries only 10 tons, it’s operating at 50% capacity utilization.

Fleet utilization is key as it directly impacts the cost efficiency of a fleet. Unused or underused vehicles represent sunk costs in acquisition, maintenance, insurance, and licensing.

Additionally, a high fleet utilization rate might indicate that the vehicles are overused, which could result in increased maintenance costs and shorter vehicle lifespans.

Cost per Mile

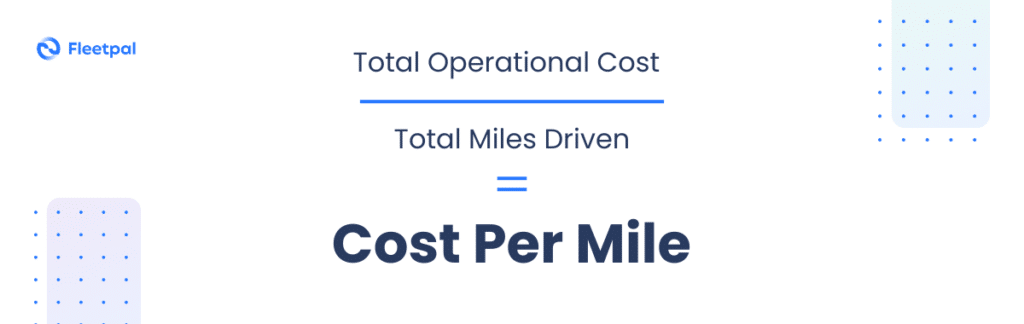

Cost per mile is another critical fleet management KPI, representing the total operational cost of running the fleet vehicles for each mile driven.

This fleet KPI is essential as it demonstrates the cost-effectiveness of fleet operations, offering actionable insights that can help fleet managers optimize costs.

To calculate the cost per mile, you take the total operational cost of running the fleet during a specific period and divide it by the total number of miles driven during that period.

Keep in mind that the total operational cost can include various expenditures such as fuel, maintenance, insurance, depreciation, and overhead costs.

By monitoring the cost per mile, fleet managers can identify trends and anomalies that may signal inefficiencies or opportunities for cost savings. For instance, a sudden increase in cost per mile could indicate that vehicles require more maintenance or that fuel consumption has become less efficient.

Fuel Efficiency

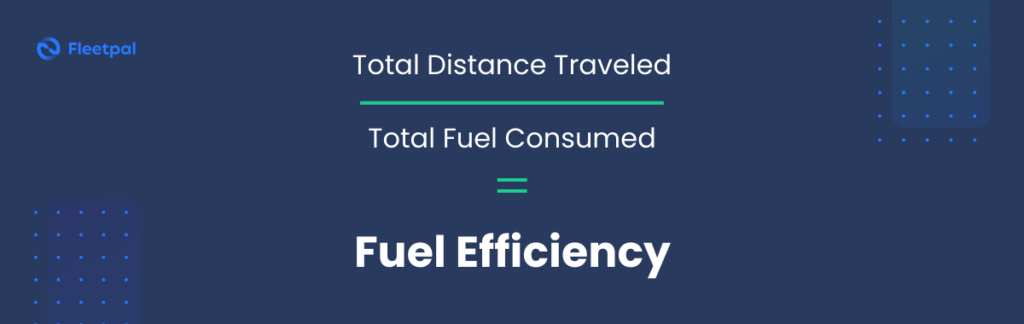

Fuel Efficiency signifies the average distance that a vehicle can travel per unit of fuel. In the USA, the standard measurement is typically miles per gallon (MPG).

Fuel efficiency is a fundamental KPI as it directly correlates with the operational costs of a fleet. A vehicle with higher fuel efficiency requires less fuel to travel the same distance as compared to a vehicle with lower fuel efficiency.

To calculate fuel efficiency, you need to divide the total distance traveled by the amount of fuel consumed:

It’s important to note that fuel efficiency can be influenced by the vehicle’s model, the driver’s driving behavior, vehicle maintenance practices, route selection, vehicle load, and more.

Keep in mind that some of the popular ways for fleet managers to significantly improve their fleet’s fuel efficiency are driver training, regular maintenance, route optimization, and potentially investing in more fuel-efficient vehicles.

Vehicle Total Cost of Ownership (TCO)

Vehicle Total Cost of Ownership or TCO represents the complete cost incurred for a vehicle over its entire lifecycle within the fleet.

This KPI provides a comprehensive view of the cost-effectiveness of a vehicle, beyond the initial purchase price.

To calculate TCO, all expenses associated with owning, operating, and eventually disposing of the vehicle are considered. These costs are divided by the number of years or miles that the vehicle is expected to last, providing a cost-per-year or cost-per-mile basis for comparison.

TCO components typically include acquisition costs, operational costs, depreciation, disposal or resale value, administrative costs, and downtime costs.

Understanding the TCO of each vehicle in a fleet can help fleet managers make informed decisions about vehicle acquisition, maintenance strategies, replacement timing, and disposal methods.

For example, a truck with a low initial purchase price but high maintenance costs may have a higher TCO than a more expensive vehicle that is cheaper to maintain and operate.

By considering TCO, fleet managers can optimize their fleet for both cost-effectiveness and operational efficiency.

Fleet Maintenance KPIs

Unlike fleet operation KPIs, fleet maintenance KPIs focus on how well you maintain your fleet vehicles.

Here are the fleet management KPIs you need to be aware of under this category.

Preventative Maintenance Compliance

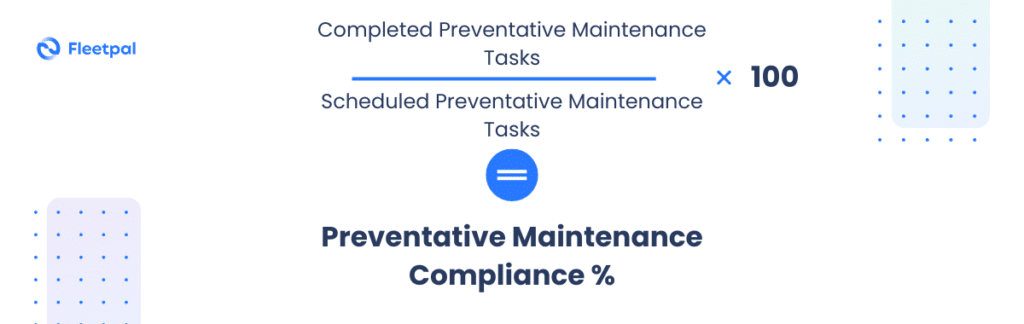

Preventative Maintenance Compliance measures the percentage of scheduled preventative maintenance tasks (PM intervals) that are completed on time.

This refers to regular, scheduled service tasks designed to prevent unexpected breakdowns and failures, thus improving vehicle safety, reliability, and lifespan.

The formula to calculate Preventative Maintenance Compliance is:

For example, if your fleet had 100 preventative maintenance tasks scheduled in a month and you completed 95 of them on time, your Preventative Maintenance Compliance rate would be 95%.

High compliance rates show that your fleet is well-maintained and that you’re doing a good job of scheduling and managing maintenance tasks.

Keep in mind that preventative maintenance can include a variety of tasks such as oil changes, tire rotations, brake inspections, fluid checks, and more. The specific schedule for these tasks can vary based on the vehicle make and model, how the vehicle is used, and the environment in which it operates.

Average Vehicle Downtime

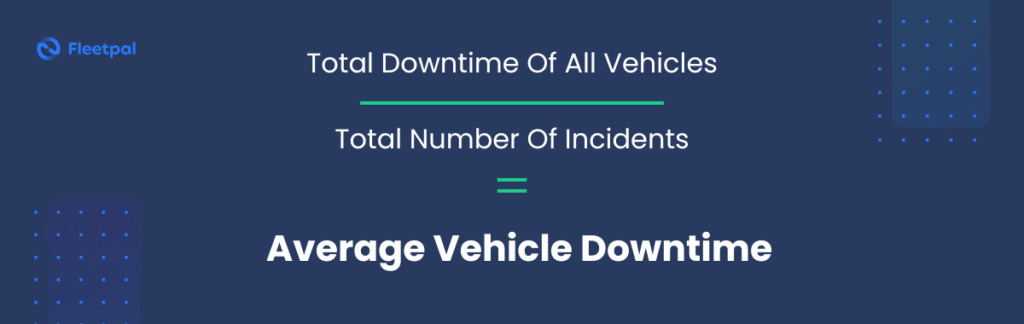

Another vital component from the fleet management KPIs list is Average Vehicle Downtime – the average length of time that vehicles in the fleet are unavailable due to maintenance, repairs, or other unexpected issues.

This downtime can significantly impact fleet operations, leading to missed deadlines, lower productivity, and increased costs.

The formula to calculate Average Vehicle Downtime is:

For example, if in a month, your fleet experienced 10 incidents leading to 50 hours of total downtime, your Average Vehicle Downtime for that month would be 5 hours per incident.

A lower Average Vehicle Downtime is generally desirable as it means that vehicles are available and operational for a larger percentage of the time.

However, reducing downtime often requires a proactive approach to maintenance, including a strong preventive maintenance program, swift response to reported issues, and potentially investing in more reliable vehicles or parts.

Repair Costs

Repair Costs is a fleet management KPI that refers to the total expenses incurred to keep the fleet’s vehicles in good working order.

These costs include the price of parts, labor charges for technicians, and any associated expenses like towing or temporary vehicle replacement costs.

To calculate Repair Costs, all the individual repair expenses for each vehicle within a specific time period, typically a year, are added together. Some businesses may choose to analyze this on a per-vehicle basis, while others may look at the fleet as a whole.

This KPI is critical because it directly impacts the total operational costs of the fleet. High repair costs can signal several possible issues, such as:

- Aging fleet – Older vehicles typically require more frequent and costly repairs. High repair costs could suggest it’s time to replace some older vehicles.

- Maintenance issues – If preventive maintenance isn’t conducted regularly, minor issues can turn into major problems, leading to more expensive repairs.

- Driver behavior – Aggressive driving habits can lead to more wear and tear on vehicles, resulting in higher repair costs.

Setting a Repair Costs KPI and monitoring it regularly can help fleet managers identify trends and areas for improvement.

Suppose repair costs are consistently exceeding the budget. In that case, it might be a sign that preventive maintenance needs to be improved, driver training might be necessary, or it may be more cost-effective to replace aging vehicles.

Moreover, fleet managers can set realistic targets for improvement and track progress towards those goals by benchmarking and comparing Repair Costs KPI with industry standards or past data.

Vehicle Part Inventories

Vehicle Part Inventories, on the other hand, refer to the quantity and value of spare parts kept in stock for vehicle maintenance and repair activities.

This KPI measures the balance between having sufficient parts on hand to avoid delays in maintenance and repairs. It also enables managers to avoid overstocking which can lead to increased inventory costs and waste due to parts obsolescence.

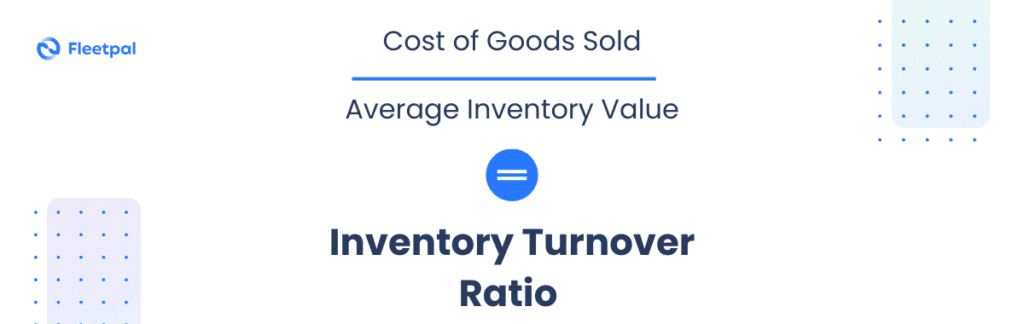

A typical way to measure Vehicle Part Inventories KPI could be through the inventory turnover ratio, which is calculated as:

In the context of fleet management, the COGS would be the cost of the vehicle parts that were used in a specific period. On the other hand, the Average Inventory Value would be the average value of the vehicle parts inventory during that period.

A higher turnover ratio suggests that inventory is used and replaced frequently, indicating efficient inventory management.

Fleet managers can better manage their spare parts inventory by setting the Vehicle Part Inventories KPI and monitoring it regularly.

This could involve strategies such as just-in-time inventory management, where parts are ordered as needed, or setting optimal reorder points and quantities based on past usage data and predicted future needs.

Driver Behavior and Activity KPIs

Lastly, the Driver Behavior and Activity KPIs all measure your drivers’ efficiency, safety, and effectiveness of your drivers.

Safety Incidents Rate

The Safety Incidents Rate KPI quantifies the frequency of safety-related incidents, such as accidents, violations, and near misses involving fleet vehicles within a specific period.

The formula to calculate Safety Incidents Rate is:

This rate is typically expressed per 1,000,000 miles driven to provide a standard for comparison, though the denominator can be adjusted to suit the size and operation of the fleet.

This KPI is critical as it shows driver safety and regulatory compliance. Additionally, it also impacts financial performance and operational efficiency.

By incorporating the Safety Incidents Rate KPI and monitoring it regularly, fleet managers can identify trends and take corrective action, such as driver training or vehicle maintenance.

Investigating each incident to understand its cause and implement preventive measures is important. This could include initiatives like safe driving programs, preventive maintenance to keep vehicles safe, and use of technologies like telematics to monitor driver behavior.

Driver Productivity

Driver Productivity measures the efficiency and effectiveness of a driver in performing their tasks.

The precise metrics used can vary depending on the nature of the fleet operations, but they often include measures such as the number of deliveries made, miles driven, or hours on the road per shift.

High driver productivity means more tasks are being completed in less time, which can lead to improved operational efficiency and potentially higher profits.

The KPI also influences cost management, human resource management, and customer satisfaction.

Speeding, Acceleration, and Harsh Braking

Speeding, Accelerating, and Harsh Braking measure specific aspects of driver behavior that can significantly impact safety, vehicle wear and tear, and fuel efficiency.

These fleet management KPIs are typically tracked using fleet telematics systems, which use GPS and onboard sensors to monitor vehicle speed and movements. The data can then be analyzed to identify trends and patterns in driver behavior.

Setting and monitoring these indicators is essential for safety, vehicle maintenance, fuel efficiency, and reputation management.

They can help fleet managers identify and correct unsafe or inefficient driving behaviors, improving safety, lower maintenance and fuel costs, and better reputation management.

Road Safety Compliance

Road Safety Compliance alternatively measures the extent to which drivers and the fleet adhere to road safety laws and regulations.

These can include adherence to speed limits, seatbelt use, compliance with hours-of-service regulations, and avoidance of driving under the influence of alcohol or drugs.

A high Road Safety Compliance rate indicates that drivers adhere to safety rules and regulations. In contrast, a low rate may signal that further training or corrective actions are required.

Setting and monitoring the Road Safety Compliance KPI is essential as it provides an overview of safety and meeting legal obligations, which can influence reputation and efficiency.

By setting and monitoring the Road Safety Compliance KPI, fleet managers can ensure adherence to safety rules, prevent accidents, fulfill legal obligations, and protect the company’s reputation and financial health.

Tracking Your Fleet Management KPIs With Fleetpal

As you can imagine, tracking all of these fleet KPIs without a reliable fleet management KPI dashboard or digital solution is a mission impossible.

Fleetpal is here to help with powerful fleet maintenance software, featuring easy-to-read data widgets and advanced reporting capabilities.

Not sure how to get started? Schedule a free online demo and let one of our team members show you how and answer all of your questions.